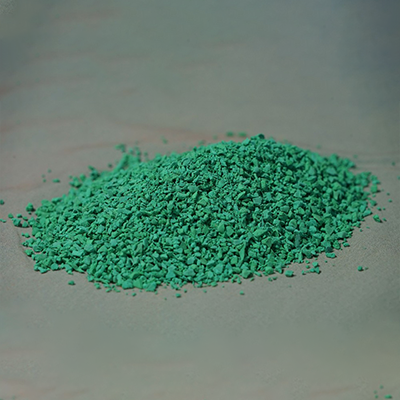

UV-resistant rubber crumbs for playgrounds & sports surfaces, available in multiple colors

EPDM rubber granules are the premium choice for playgrounds, kindergartens, and sports surfaces. Renowned for their eco-friendly composition, superior elasticity, and vibrant fade-resistant colors, these granules deliver unmatched durability and safety. The porous texture minimizes glare from sunlight, while the UV- and ozone-resistant formula ensures long-lasting brilliance—ideal for custom designs, multi-color patterns, and high-traffic areas.

Product Information

Key Features

- Child-Safe & Eco-Friendly: Non-toxic, heavy-metal-free, and made from recycled materials.

- All-Weather Durability: Resists cracking, fading, and temperature extremes (-30°C to 80°C).

- Impact Absorption: Reduces injury risks with excellent shock attenuation (tested to ASTM F1292).

- Anti-Slip & Low Maintenance: Textured surface enhances traction; resistant to mold and mildew.

- Design Flexibility: Available in 10+ standard colors for creative layouts (custom blends optional).

Applications

- Playgrounds & school safety surfacing

- Athletic tracks & sports fields

- Park trails & recreational pathways

- Roof gardens & pool surrounds

Premium Material Suppliers

Sourced from industry leaders: Clariant, DIC Corporation, BASF, ExxonMobil.

1. What is EPDM rubber granules used for?

EPDM rubber granules are widely used in safety surfacing for playgrounds, sports tracks, gym flooring, and landscaping applications. Known for their excellent UV resistance and weather durability, EPDM granules are ideal for outdoor and high-traffic environments. They are often mixed with polyurethane binder to form colorful, seamless, and impact-resistant surfaces.

2. Is EPDM rubber safe for playgrounds and kids?

Yes, EPDM rubber is considered safe for playground use. It is non-toxic, heavy-metal-free, and meets EN1177 and ASTM standards for impact attenuation. Its soft and elastic surface provides excellent fall protection, making it ideal for children’s play areas, schools, and daycares.

3. EPDM vs SBR rubber granules – what’s the difference?

While both EPDM and SBR rubber granules are used in safety surfacing, they differ in material properties and applications. EPDM is made from virgin rubber and offers superior UV resistance, color stability, and durability, making it ideal for top layers. SBR is made from recycled tires and is more cost-effective, commonly used as a base layer. Choosing EPDM ensures longer-lasting and more vibrant results.

4. How long does EPDM rubber flooring last?

EPDM rubber flooring can last 8–15 years or more, depending on usage and maintenance. Thanks to its weather resistance, EPDM surfaces maintain their elasticity and color over time. Regular cleaning and proper installation can significantly extend the life span of the flooring.

5. Best EPDM rubber granules suppliers in China / Asia / Europe

When looking for reliable EPDM rubber granule suppliers, consider manufacturers with ISO certifications, REACH compliance, and proven export experience. Chinese suppliers often offer competitive prices and customized solutions for different markets. Our company specializes in high-quality EPDM rubber granules with consistent colors, sizes, and excellent UV stability — trusted by global clients across Europe and North America.

6. How to install EPDM rubber granules on playground surface?

Installing EPDM rubber granules typically involves mixing the granules with a polyurethane binder and spreading them evenly over a prepared base layer. The process includes surface cleaning, base preparation (often with SBR), and trowel or machine application of the EPDM layer. Installation should be done by professionals to ensure proper curing and durability.

8. Are EPDM rubber granules eco-friendly or recyclable?

EPDM rubber granules are considered environmentally friendly. They are made from non-toxic, virgin rubber compounds and are free from harmful heavy metals. While EPDM itself is not typically recycled post-installation due to its bonded form, its production process is relatively clean, and many manufacturers are adopting sustainable practices.